tested by Ivano Mangiorino

Foto from Silvia Dogliani

Marco Bosi's "ROSE

DES SABLES"

Reduced for the desert

Translation of the original Italian version and hosting of the HTML dokument done by Claus Possberg since 29-Jul-1997.

Related links: Possi's Webseiten - Boxer Fans in the Internet - HPN Technikdaten - Matz Rosenquist special bike story

![]() Article published un MOTO

TECNICA no. 5, maggio 1997

Article published un MOTO

TECNICA no. 5, maggio 1997

tested by Ivano Mangiorino

Foto from Silvia Dogliani

...... AN INTERESTING WORK BASED ON A BMW BIKE, RIDDEN POWERFULLY AND WITHOUT PROBLEMS IN AFRICA

This is long raid machine, whose design approach has logically provided the bike functionality and affordability, without any concession to stylistic refinements. The final result is a very specialized bike with great attention paid to all details and the ability to be self-reliant on long distance trips.

|

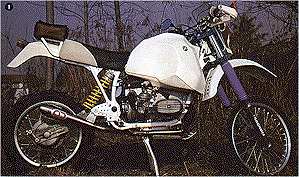

PICTURE 1: a short solo seat and a big 45 litres tank are typical features of this "stripped down" desert bike that, in spite of its majesty, seems to feel at ease on this kind of sandy soil. Starting from a quiet G/S 80, a carefully renovation has resulted in a highly efficient, specialized machine. |

TECHNICAL IMPROVEMENTS TO THE FRAME

The performance of BMW boxer in every situation has always been a warranty of reliability, that's why modifications made to the engine haven't been as rigorous as those made on the frame of our R 80 G/S. Let's explain right now: the standard bike is not scrap, but to face hard raids, some suitable strenghtening is appropriate to allow the frame to work in the harsh environments: the basic frame is good and, with your knowledge of where you can operate, this machine will go to the desert or offroad and will survive for a long time.

|

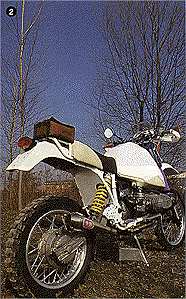

PICTURES 2 - 3: However high and imposing, this BMW is easily handled, thanks to the low barycentre obtained with the boxer. The trim is typically offroad, with the most work being done on the suspensions and, consequently, on the frame. The entire bike is made with great care, maybe not with a great excess of aesthetics, but with an absolute seriousness about the effectiveness and strenght of every single component. |  |

The cradle is still the original one, but reinforced around the long arm pin with large steel plates, which are also to support the exhaust system; a similar reinforcements has been added to the rear shock connection of the frame....

In fact, as the frame of BMW G/S must encircle a big engine crankcase, the structure is fairly wide. So it's not a bad idea, when you want to get a more specific use of the bike, to apply some reinforcements that improve the original strenght. That's not a stiffness question, since an offroad frame is different , in this sense, from a street one: in this case the frame must "work" in accord with the suspensions. Excessively stiff frames run the risk of cracks forming in the most critical points.

|

|

| PICTURE 4: The electrical system of this bike has been completely re-built. In addition to the tachometer, km counter and warning lights it has been configured to receive an electronic tripmaster and a satellite navigator (not shown here) . We notice the very strong execution of the brackets for the front fairing and the instrument panel. | PICTURE 5: The front fork is a multi-adjustable 45 mm Marzocchi Magnum 300 mm dumping; On the brake we can see a floating 260 mm disc by Brembo with a 4 pistons caliper , jointed with an ergal bracket. On the front wheel hub is the electronic trip master sensor and its magnet. |

As a result, on this bike some brackets have been welded in the wide part of the cradle and in proximity of the steering head to face the intense condition that the lenght of the front fork may cause. This one is a 45 mm Marzocchi Magnum with 300 mm running that transfers higher vibrations to the frame due to its its greater stiffness. The distance between the upper and the lower fork head has been increased by 20 mm, to gain more stiffness in the steering (more strenght to oppose lower parts bending) but this is prejudical to the stillness of the frame.... Since we are talking about suspensions, on the back we can see the classic monolever of GS models, but it is replaced with a light aluminium arm built by TAG and obtained with a valuable casting.

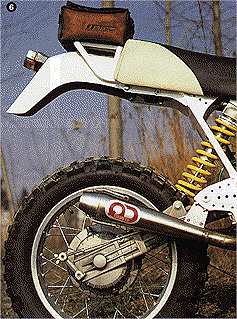

TAG's arm, besides being 100 mm longer than the standard one, allows wheels with larger tires (Michelin Desert in this case, size 140/90/18) to be mounted. This reduces the side displacement of the rear wheel towards the front one. Installing this type of tire, keeping the standard arm, should be necessary to slap the rear wheel to the left side about 14 mm; this aluminium swinging arm allows to slap the final drive canister to the right side 10 mm. The final result being the rear wheel is located to the left but only (14 - 10) 4 mm.

|

|

| PICTURE 6: simple and linear in design, the monolever swinging arm has been replaced by a new one more suitable for the hardest use. The rear drum brake is the standard one. | PICTURE 7: The rear wheel has been displaced by 14 mm to allow the mounting of a wider tire. |

Regarding wheels alignment on standard bikes, it's easier than you can think to find new bikes with wheels not at the same level. In a production line, tolerances are usually restricted. BMW allows for the new oilhead bikes a maximum misalignement of 9 mm among the wheels, so.... Rear shok linked to this arm is a special Ohlins with a remote reservoir, and a longer run (+ 8 mm) compared to the standard Ohlins available for this kind of bike. The wheel run is about 300 mm.

Modifications on the rear frame consist of a new subframe built with special Chrome-Molybdenum steel tubes, screwed with bolts at the original connections.

|

|

| PICTURE 8: Details of the swinging arm and the Ohlins shock which is , of course, multi-adjusting : spring pre-load and braking on both sides. This one has a longer centre to centre distance to gain more travel at the wheel and to line up with the new front fork. | PICTURE 9: Obtained with an earth fusion, the swinging arm is a valuable option especially if you want to keep the original monolever.... |

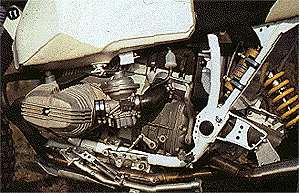

The 1043 cm3 displacement on this boxer has been obtained with a couple of 97 mm forged pistons linked to the R 80 G/S 70,6 mm running ; connecting rods are not standard since they've been replaced by titanium pieces.....The rest of the base is standard, with electric starter..... In the cylinder heads, where ducts have been mirror polished, we can also see a 46 mm inlet valve and a 38 mm outlet valve, with the classic 40 mm Bing carbs.

|

|

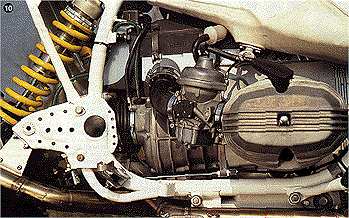

| PICTURE 10: The powerful engine has been overhauled with care and some special parts have been mounted, like forged pistons, and titanium connecting rods to gain (if necessary) reliability rather then performance. | PICTURE 11: With such a big engine, in fact, the couple is always enough to go out of the large offroad traps.....It may be difficult (depending on the biker) on a mule-track, but BMW bikes weren't built for this use.... |

|

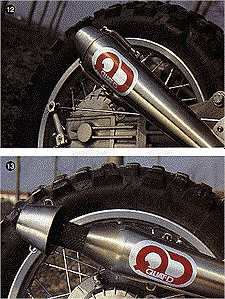

PICTURES 12 AND 13: two detailed pictures of Quat-D exhausts with removable mufflers, to get the engine completely free. With opened megaphones you cannot ride in the urban contest, but with complete mufflers. |  Marco Bosi |